Your Advantages with STAUFF

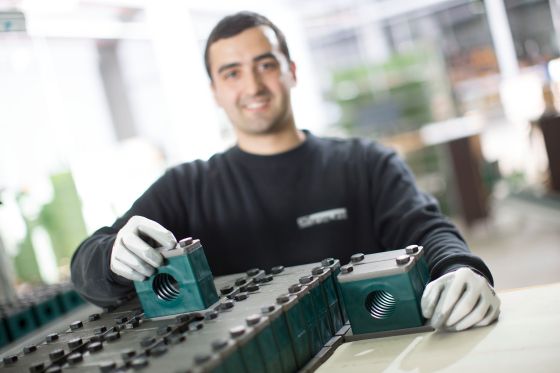

Quality Manufacturer

Development and manufacturing in Germany

Premium Offer

Products in uniformly high, coordinated quality

Project Partner

Experience and know-how from planning to implementation

Global Network

Availability and service in all industrial regions

STAUFF Australia Corporate Video

News from STAUFF

Latest product news, business and company news as well as other general news from the STAUFF Group

Your Payment Options on the STAUFF Digital Platform